FROM THE DRAWING TO THE INDIVIDUAL SOLUTION

OPTIMALLY COORDINATED DESIGN AND PRODUCTION. It is not unusual for furniture components to have to fulfil two contradictory requirements: They must be attractively designed and at the same time fulfil very sober technical specifications. For example, the technically required stability must be achieved with the most economical use of materials possible. We achieve these requirements by coordinating design and production right from the drawing board. Modern analysis programs and simulation tools help us to do this.

Together with the customer we sketch first ideas in a concept and design phase:

WHAT IS THE SPECIFIC REQUIREMENT?

WHAT IS THE CHALLENGE?

We develop numerous solutions on the drawing board, which we discuss, test and validate technically.

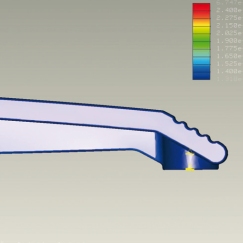

CAD models and simulations are an important basis for production preparation

Physical analyses make load lines visible. This allows us to see where we need to reinforce material and where we can save it.

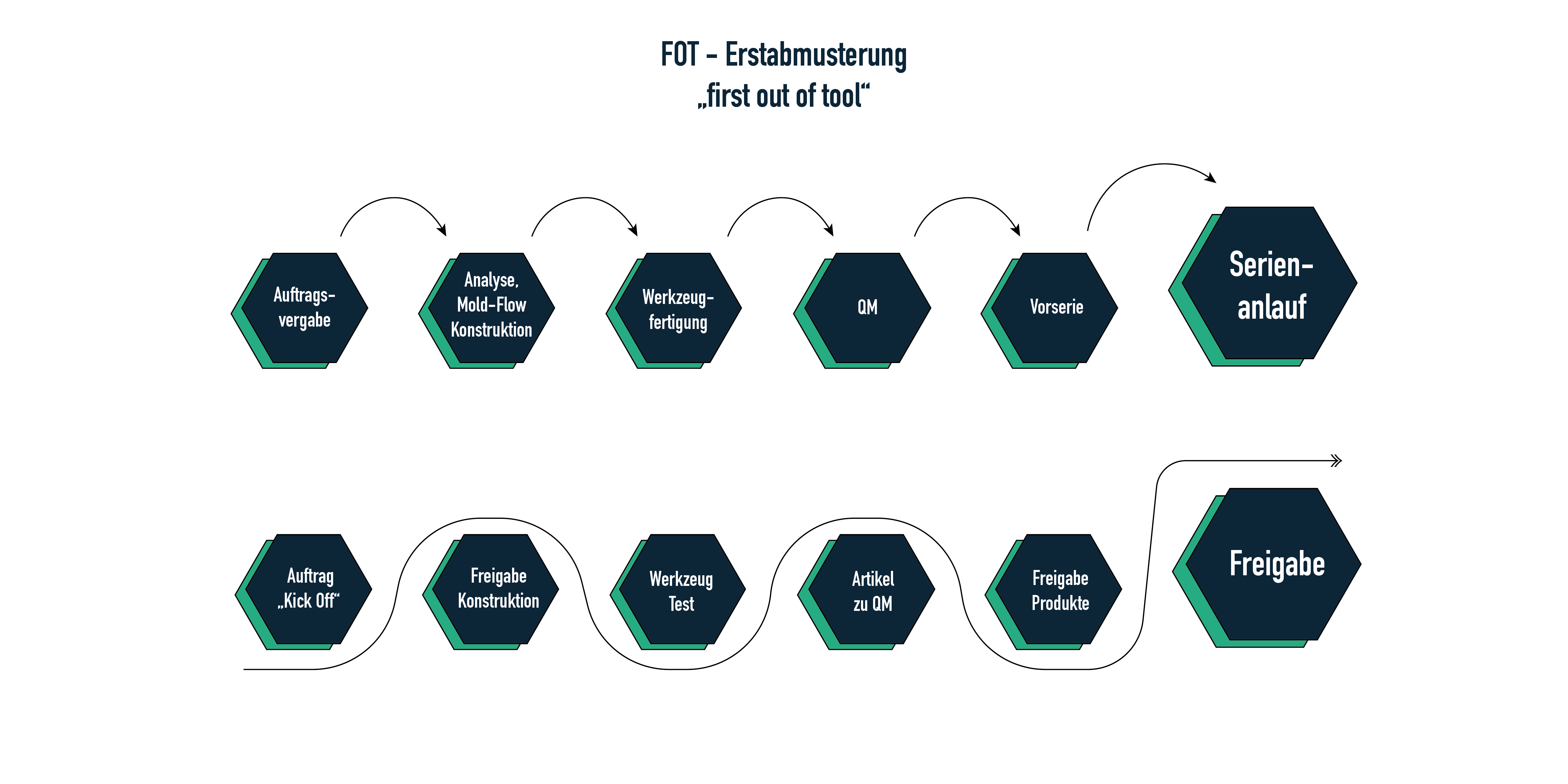

Toolmaking summarizes our know-how. Because optimal tools fulfill our specifications for technical product design and are the basis for efficient production.

We test new products in the prototype phase and also during ongoing production

At the end the serial production is waiting...and an enthusiastic customer!