Conserving resources with proroll

How we save energy

At proroll, we see environmental protection not only as an obligation, but also as an opportunity to achieve competitive advantages through environmentally friendly products and resource conservation. Within the company, we also ensure that our daily actions in all areas of the company protect the environment instead of burdening it. Beyond the legal requirements, we are continuously working to improve our environmental performance.

It is important to us that we as a company consume as little energy as possible. We rely on forward-looking technology and renewable energies and try to implement this in all areas. Every saving counts, no matter how small it is.

f.l.t.r.

Dirk Adler / Communication / proroll

Stefan Fornahl / CEO / proroll

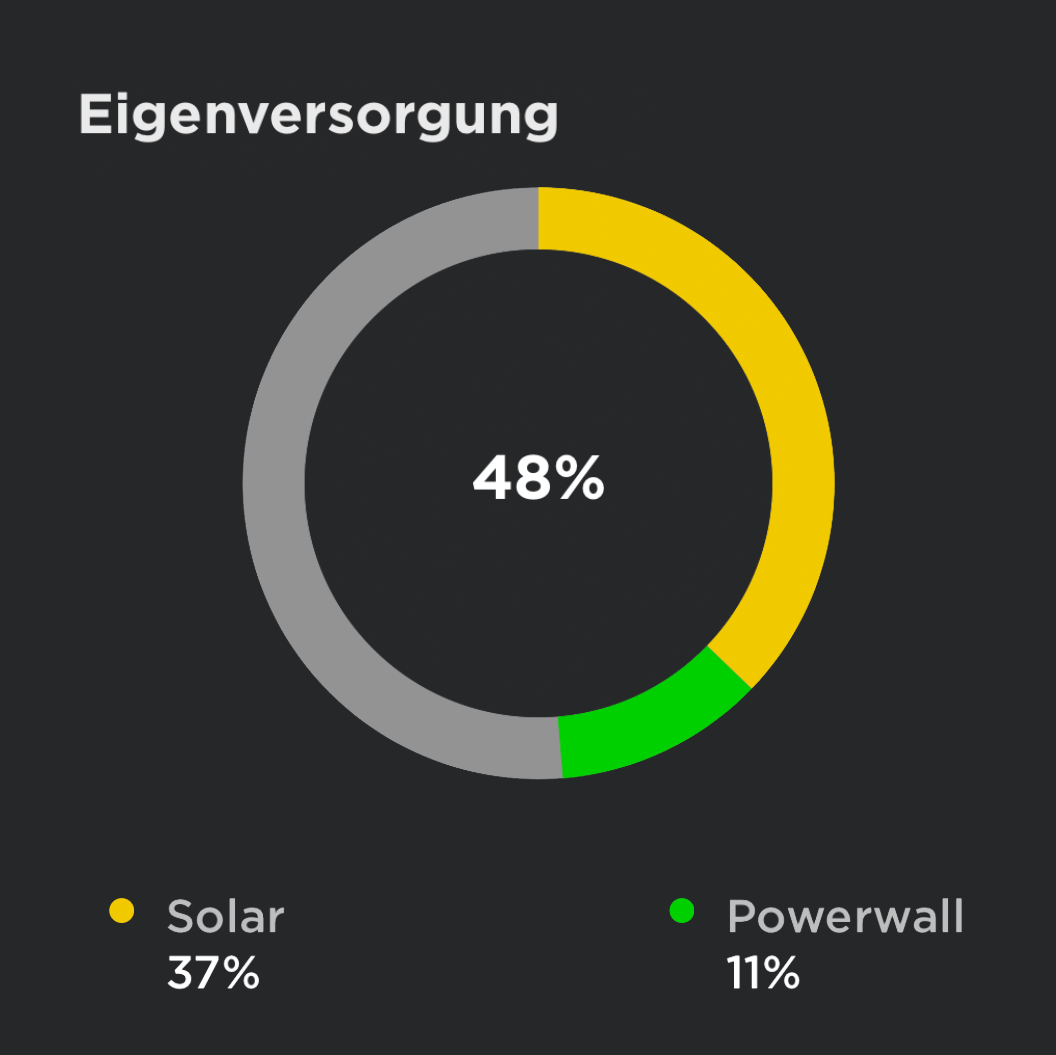

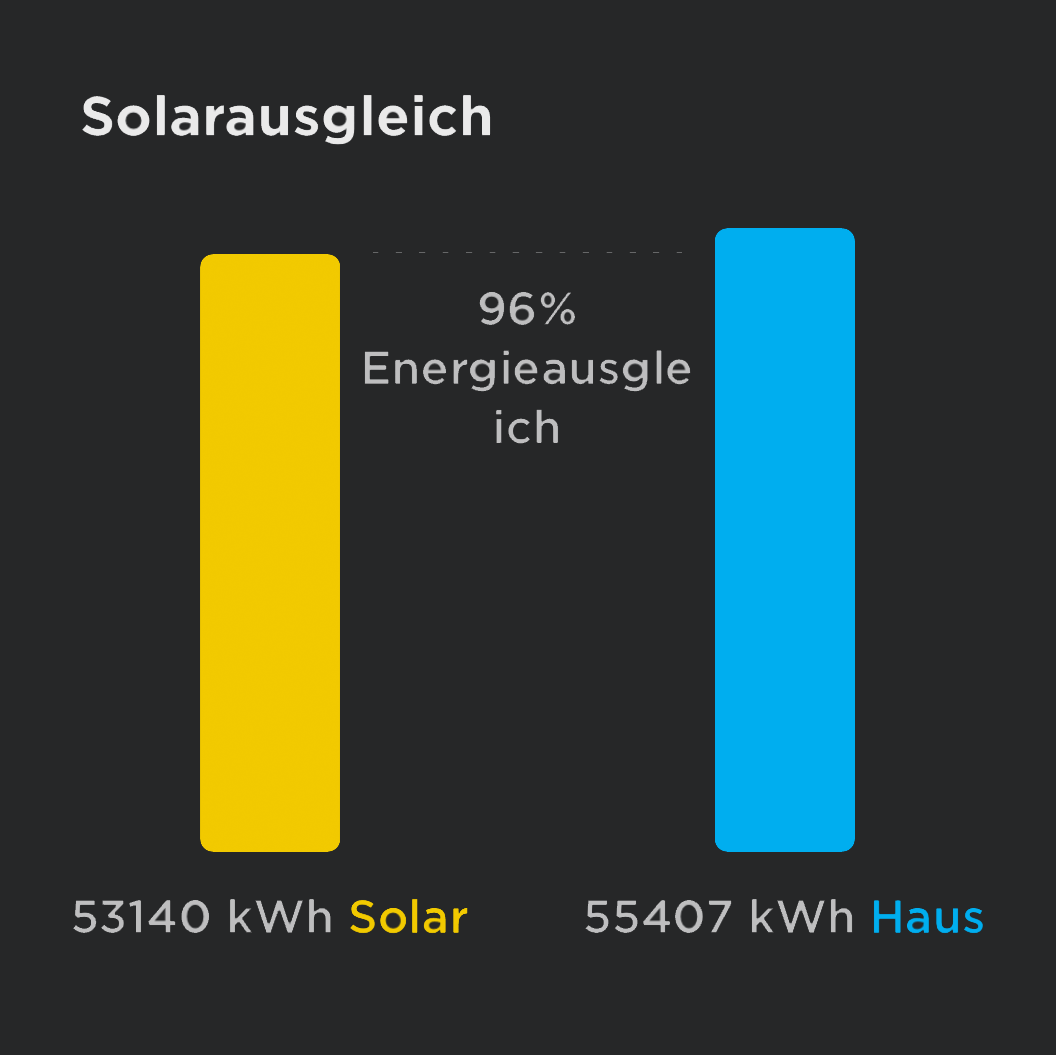

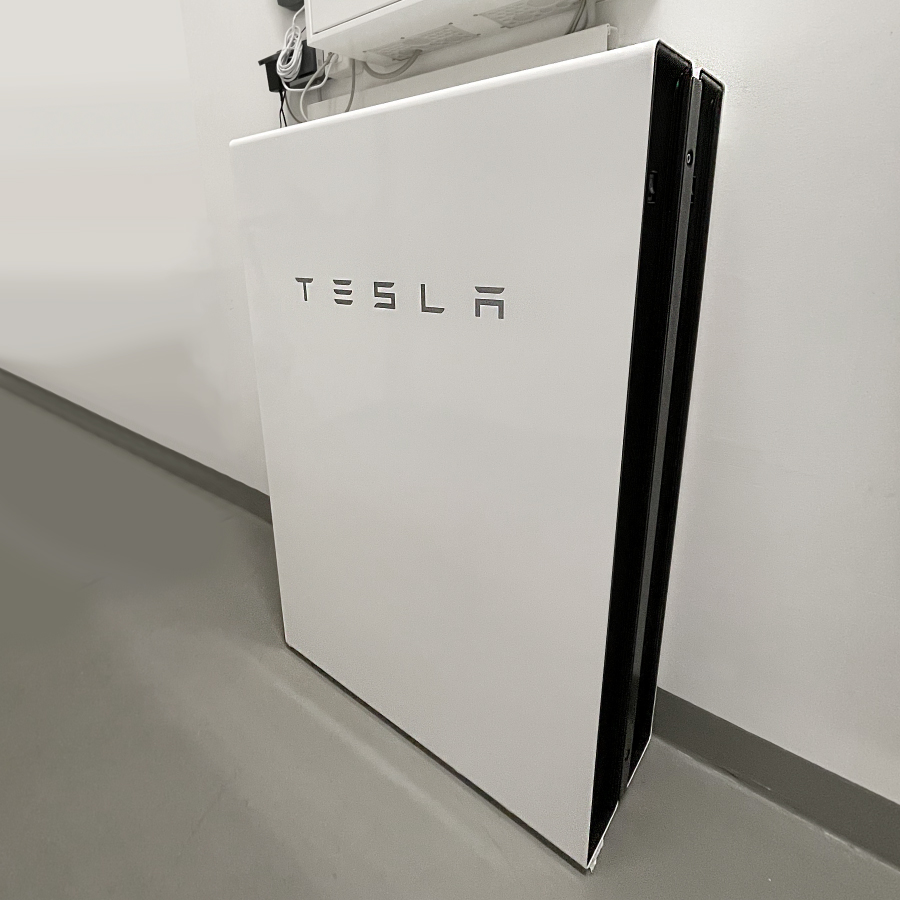

A photovoltaic system of 60 kW at the main site in Hückeswagen, which is precisely matched to the energy requirements, provides almost enough energy that the company needs all year round. The more "proroll bio-electricity" is fed into the public grid and further ensures sustainability there. In addition to the positive decrease in the consumption of non-renewable energy resources, the photovoltaic system will also lead to a reduction in CO2 emissions.

Savings through improvement

A big heartfelt wish of the staff and management after the completion of the PA system was the charging of e-cars for employees and customers. Free charging for all employees with our self-produced green electricity is a matter of course for us. Everyone is happy about the sustainable LED light in the entire production and warehouse. Also because there is now even more to see, with brighter light.

Complete LED electrification and lighting in the building and the outdoor area

Savings through investments

These will pay off for the company over the years and provide more comfort. For example, the replacement of the aging compressor system brought tidy savings. 50% Energy saving and an additional noise reduction of almost 80%. Or fine tuning the Quick-closing gates with movement sensors that only leave a door open as long as it is really needed. This ensures savings of thermal energy between production and warehouse.

Energy efficient compressor unit. Savings 50% compared to the old system

Saving through change

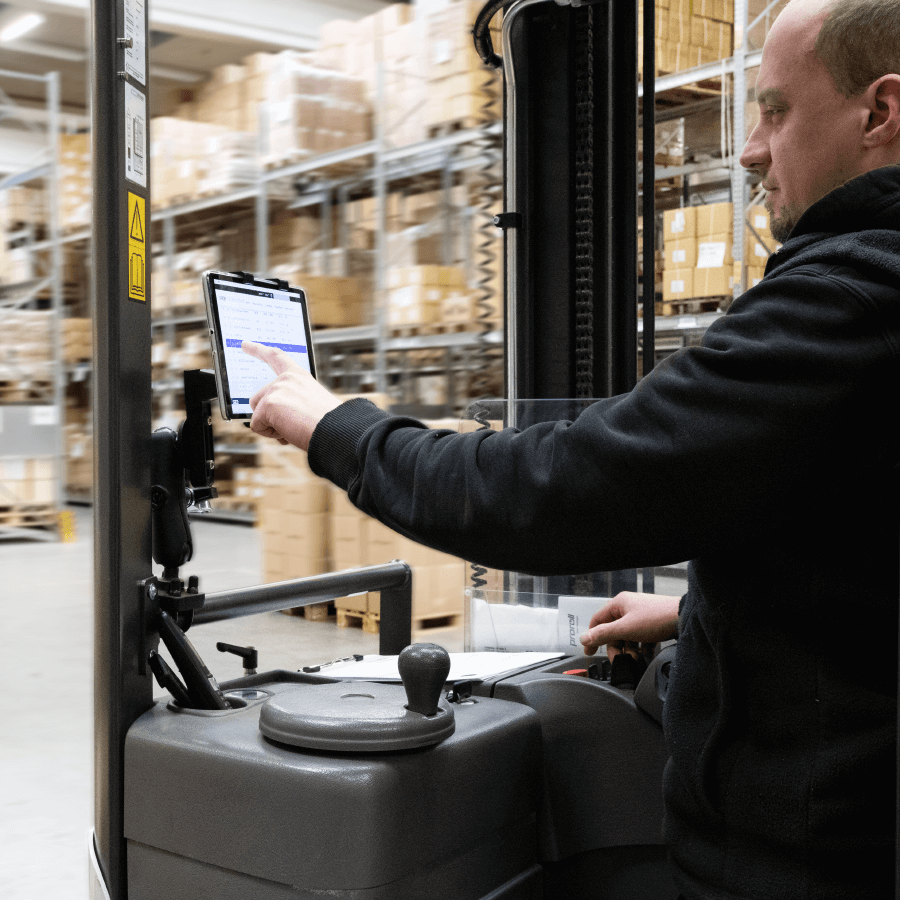

Small changes often have multiple benefits. Equipping the assembly and logistics departments with tablets primarily led to shorter routes and a better flow of information. Secondarily, it also ensured at the same time an enormous paper savings which wasn't even planned in the beginning.

Save paper by equipping production and assembly with tablets

... the road continues